Automatic Pouch Packing Machine

Automatic Pouch Packing Machine

Enquiry Now

Introduction of Automatic Pouch Packing Machine

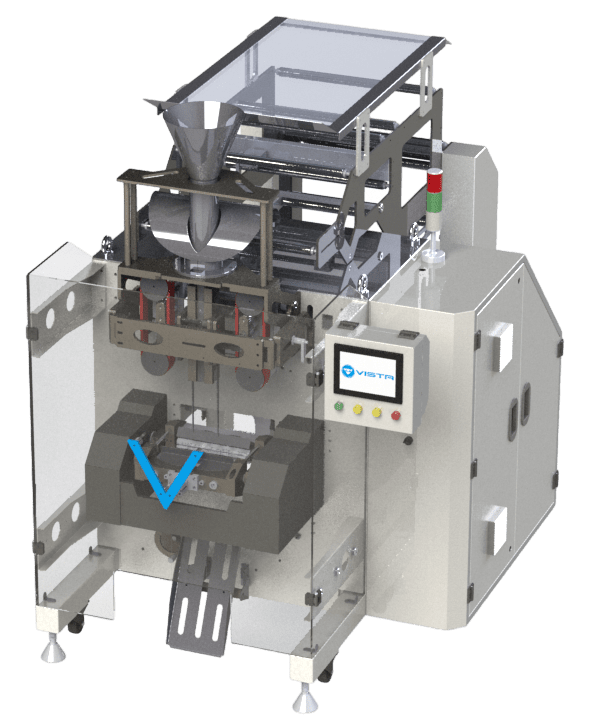

An automatic pouch packing machine is a sophisticated piece of equipment designed to streamline the packaging process by automatically filling and sealing pouches with various products. This machine is widely used across industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals to efficiently package powders, granules, liquids, and solids into pouches of different sizes and materials. With advanced technology and precision engineering, these machines ensure high-speed, accurate, and hygienic packaging, making them essential for modern production lines.

Technical Specifications of Automatic Pouch Packing Machine

-

Filling Mechanism: Utilizes volumetric, gravimetric, or auger-based filling systems to accurately dispense the product into pouches.

-

Pouch Types: Compatible with a wide range of pouch styles including pillow pouches, stand-up pouches, zipper pouches, and spout pouches.

-

Packaging Materials: Supports various packaging materials such as laminates, polyethylene (PE), polypropylene (PP), and aluminum foils.

-

Filling Capacity: Offers adjustable filling capacities to accommodate different product volumes and packaging requirements.

-

Sealing Method: Utilizes heat sealing, impulse sealing, or ultrasonic sealing techniques to create airtight seals on pouches.

-

Control System: Equipped with advanced PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) for precise control over filling, sealing, and machine parameters.

-

Speed: Provides high-speed packaging capabilities, with adjustable speeds to match production requirements.

-

Integration: Can be integrated with auxiliary equipment such as conveyors, checkweighers, metal detectors, and inkjet printers for a complete packaging line solution.

Features of Automatic Pouch Packing Machine

-

Fully Automatic Operation: Enables hands-free operation with automatic pouch feeding, filling, sealing, and discharging, minimizing manual labor and increasing productivity.

-

Versatile Filling Options: Supports filling of various products including powders, granules, liquids, and solids, making it suitable for diverse packaging applications.

-

Quick Changeover: Facilitates fast and tool-less changeovers between different pouch sizes, products, and packaging formats, reducing downtime and maximizing uptime.

-

Customizable Settings: Allows for adjustment of filling parameters such as fill volume, fill speed, and fill accuracy to meet specific product and packaging requirements.

-

Integrated Weighing System: Optionally equipped with weighing scales or load cells for precise filling by weight, ensuring consistent product dosing and compliance with regulatory standards.

-

Quality Control Features: Incorporates sensors and inspection systems to detect and reject defective pouches, ensuring packaging integrity and product quality.

-

User-Friendly Interface: Features intuitive controls, touchscreen displays, and recipe management functions for easy operation and setup by operators.

-

Safety Measures: Includes safety interlocks, emergency stop buttons, and protective guards to prevent accidents and ensure operator safety during machine operation.

Benefits of Automatic Pouch Packing Machine

-

-

Increased Efficiency: Automates the packaging process, reducing manual labor and increasing production output, resulting in higher efficiency and throughput.

-

Improved Accuracy: Provides precise and consistent filling and sealing, minimizing product giveaway and ensuring packaging integrity.

-

Enhanced Productivity: Offers high-speed packaging capabilities, allowing for rapid production and faster time-to-market for products.

-

Versatility: Accommodates a wide range of products and packaging formats, providing flexibility to meet diverse market demands.

-

Cost Savings: Reduces labor costs, material wastage, and packaging errors, leading to overall cost savings and improved profitability.

-

Compliance: Meets regulatory requirements and industry standards for packaging hygiene, safety, and quality, ensuring consumer satisfaction and brand reputation.

Market Competitiveness: Enables businesses to respond quickly to market trends and customer preferences by offering attractively packaged products with superior quality and consistency.

-

Applications of Automatic Pouch Packing Machine

The automatic pouch packing machine finds applications in various industries including:

-

Food and Beverage: Packaging of snacks, spices, sauces, condiments, powders, and beverages in flexible pouches for retail and food service markets.

-

Pharmaceuticals: Packaging of tablets, capsules, powders, and granules in unit-dose pouches or sachets for pharmaceutical and healthcare products.

-

Cosmetics and Personal Care: Packaging of creams, lotions, gels, and serums in pouches for skincare, haircare, and beauty products.

-

Chemicals and Industrial Products: Packaging of detergents, fertilizers, pet foods, and industrial chemicals in pouches for commercial and industrial use.

Conclusion

Frequently Asked Questions (FAQs)

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072